Description

5M s.r.o. is a medium-sized company operating in the area of the development and manufacturing of composite and sandwich materials and related subsystems. 5M has a wide range of customers in space applications and aircraft manufacturer as well as railway transportation and electric industry. Investments to R&D are roughly 8% of the annual turnover. 5M was awarded as the Company of the Year of 2010 in the Czech Republic.

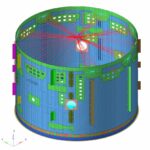

- PLATO CT

- PLATO FEM

Competences and capabilities

Development and manufacturing of structural composite parts such as sandwiches and sturts. Development mechanical subsystem for solar array, manufacturing of small size solar arrays. Design and manufacturing of radiation shielding. Development and supply of structural epoxy foli and paste adhesives, epoxy resins, pre-impregnated fabrics (prepregs, semipregs). Development and manufacturing of composite and sandwich structures for optics.

Major Space Projects & References

- Programme: TRP Name: PCDU Radiation Shielding of the JUICE SSTS Prime contractor: Airbus Defence and Space, Spain Duration: 2017-2019

- Programme: TRP Name: Critical Review and Assessment on CFRP and Polymeric Material Usage for Crew Compartments and Manned Transport Systems Prime contractor: Thales Alenia Space, Italy Duration: 2017-2019

- Programme: Third Party Project Name: Flexible Solar Array Mechanical Subsystem Prime contractor: 5M s.r.o. Subcontractors: Thales Alenia Space France, Frentech Aerospace, LK Engineering, BD Sensors and VZLU Duration: 2019-2021

Space Related Equipment, Labs & Certificates

Certificates

- AS/EN 9100:2009

- EN ISO 9001:2009

- POA PAR 21.G EASA 748/2012

- DIN 6701 A1

- IATF 16949

- 10.000 m2 area total including

- 5.000 m2 of working area totally

- 3.000 m2 of warehouses

- 1000 m2 of offices

- 300 m2 of area with controlled temperature and air filtration

- 100 m2 clean room ISO 8

- 300 m2 of labs with controlled climate

- 245 employees

- Autoclave up to 250°C, diameter 2000 mm, length 4000 mm

- Automated cutting of prepreg

- Laser positioning system for prepreg lay-up

- Several CNC machines up to part dimensions 7500 x 1400 mm

- Kuka robotic arm

- Ovens up to 250°C, dimensions of 6000 x 3000 x 2200 mm

- Presses up to 180°C, max. dimensions 3000 x 1700 mm

- Pullpress up to 180°C for various diameters

- 9 pultrusion lines Labs

- Universal testing machines, load cells up to 100 kN equipped with Environmental Chamber for temperature range from -60°C to +250°C

- Thermal cycling

- Outgassing Measurement Device

- CNC atmospheric plasma treatment 600 x 850 mm

- CTE measurement with DIL 822 (Dilatometer)

- DMA (Dynamic Mechanical Analyser)

- TGA 2 (Thermogravimetric Analyser)

- Rheometer Discovery HR1

- DSC 1 (Differential Scanning Calorimeter)

- CMM (Wenzel, max. part dimensions 3000 x 1500 x 1200 mm)

- Optical Microscopy and Defectoscopy

- Ultrasonic non-destructive testing